TRATO-TLV

DESIGNER AND MANUFACTURER OF LIGHTING EQUIPMENT (TRATO) AND HOSPITAL EQUIPMENT (TLV)

TRATO-TLV

DESIGNER AND MANUFACTURER OF LIGHTING EQUIPMENT (TRATO) AND HOSPITAL EQUIPMENT (TLV)

TRATO-TLV GROUP DESIGNS, MANUFACTURES AND COMMERCIALISES LIGHTING PRODUCTS AND HOSPITAL EQUIPMENTS IN THE WORLD.

Its workforce today is 250 employees with multiple skills and the company has a fleet of high technology machines.

For nearly 70 years TRATO, lighting division of the group, has provided architectural and custom-made lighting fittings for the tertiary sector, large-scale distribution and chains of stores, railway, subway, air and maritime transport, parking lots, clinics, hospitals and retirement homes.

Very adaptable and reacting quickly to the laws of the market, TRATO relies on high precision and compliance with the different prevailing standards, in different domains: low voltage, electromagnetic compatibilities and other European guidelines.

Today has many world-renowned firms trust TRATO for their lighting projects: our company also supports its customers in their international development.

Strength of these successes, TRATO continues to offer customized solutions and centres the development of new products on the low consumption and energy savings.

HISTORY OF THE COMPANY

KEY FIGURES 2021

of expertise

Employees

Stores provided with lighting

Annual production of luminaires

%

Export turnover

%

of turnover dedicated to R&D

SERVICES

THE TRATO RANGE IS DISTINCTLY GEARED TOWARDS SERVICE AND CONSULTING:

LIGHTING DESIGN

CONSULTING AND DESIGN

Our teams will be on-hand to imagine and design a lighting concept that is compatible with either your current or future installation and to provide you with advice with a view towards optimisation. They will advise you with regards to the desired lighting solution as well as the choice of bulbs to be installed. This level of expertise will enable you to reduce your consumption and to improve your environmental impact. A dedicated, highly-skilled team will also be on-hand to assist our clients when it comes to finalising recently fitted concepts or making the final adjustments to lights in retail outlets. We have one objective: to provide complete satisfaction from the start to the end of your project.

INNOVATION

We employ an internal research and development team who are tasked with designing our products and optimising them in terms of their efficiency. Their expertise means we are able to offer bespoke solutions that are suitable for your lighting concept. And because we are living in an ever-more connected world, TRATO is at the cutting edge when it comes to new forms of technology: LiFi, VLC, the DALI lighting management system, dynamic display lighting and dynamic fitting room lighting.

QUALITY

DESIGN OFFICE

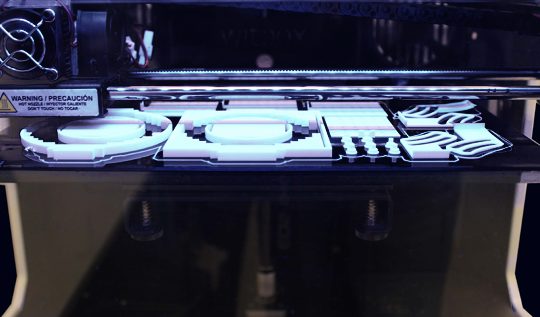

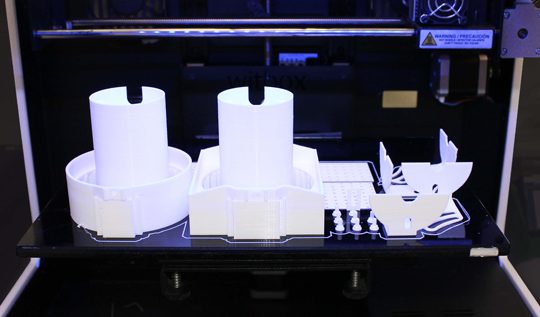

The design team constituted by engineers and designers, explores and develops products as a whole, specifications to achieve series through phases of validation and prototyping.

We offer bespoke lighting solutions for use in the retail sector. This means that clients are able to customise their lighting products so as to be able to match them to their image and their concept, creating something that is unique.

The skills of our engineering department remain varied et provide the ability to examine pieces which will be realized by means of the extrusion of aluminium or plastic, the plastic injection, the molding shell aluminium and other manufacturing process.

Our exclusive organization in terms of design and production insures you a quality of work and finishes with the utmost respect for deadlines.

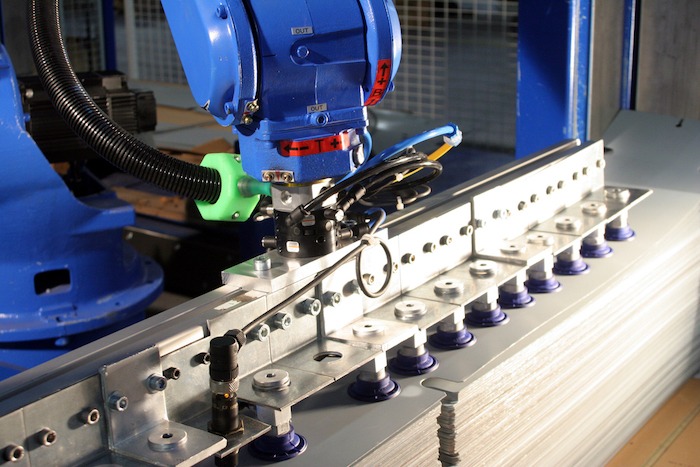

INDUSTRIAL EQUIPMENT

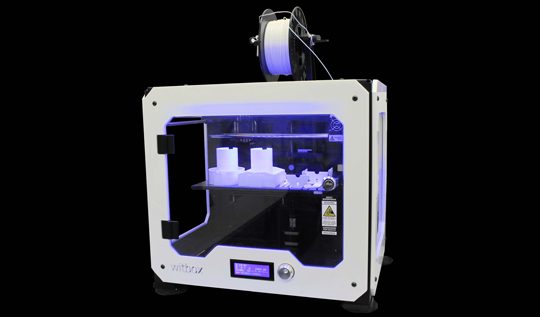

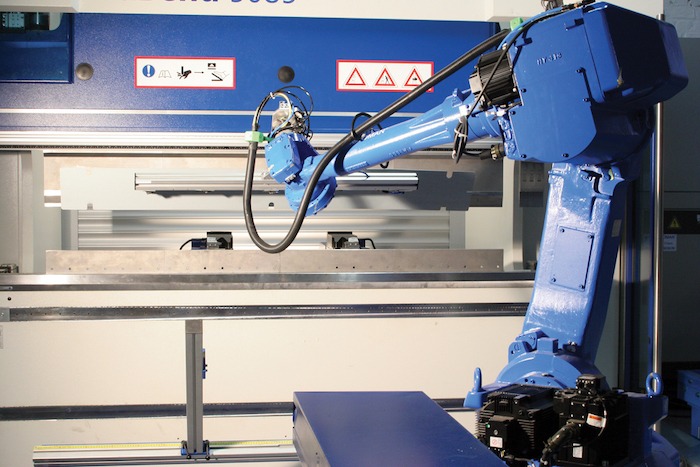

TRATO’s factory is made up of machine park of last generation with a total area of 15 000 m² located in Lille:

- Center machining CNC

- Folding robots

- Cutting machine water jet CNC

- Chain liquid paint workshop fully automated assembly

- Assembly-cabling workshop

- Robotic punching machine

QUALITY AND CSR

QUALITY CONTROL

TRATO’s quality management system is focused on our products and organization.

Trato has test benches to ensure product conformance:

- to standards-Electrical Safety (Low Voltage Directive 2006/95/EC)

- to electromagnetic compatibility (EMC Directive 2004/108 / EC)

It also has the dimensional measurement means checked and attached to the national standards by a metrology laboratory.

According to the specific products Trato also uses laboratory notified status of compliance for performance and safety accordance with European standards.

CORPORATE SOCIAL RESPONSIBILITY (CSR)

As part of its development, and to better protect future generations, the TRATO-TLV Group is committed to a policy of Corporate Social Responsibility (CSR), and has implemented a targeted and equitable approach based on three components:

- Economy

- Social

- Environmental

PARTNERS